Tapestry is a fiber art form which is most often defined as a discontinuous weft-faced weave structure. It often uses this structure to depict an image. And often, though certainly not all the time, those images are part of two-dimensional art pieces meant to hang on a wall.

There are many kinds of looms that can be used to weave tapestry. Virtually any structure that can hold a set of warp threads in order and taut will work in some fashion. Kids weave them on cardboard boxes all the time.

But for a good tapestry loom, you want something that can hold a relatively high tension. And this is not true of all looms and not even of all looms sold as tapestry looms. Looms for tapestry come in many varieties. One delineator is high-warp versus low-warp looms.

Low-warp looms have the warp running more or less parallel to the floor.

High-warp looms have the warp running perpendicular to the floor.

For the fascinating ATA educational article by Lyn Hart about Sylvia Heyden and her work, click HERE.

The loom I use the most for tapestry is a low-warp countermarche loom made by Harrisville Designs in New Hampshire, USA. This loom was designed with Peter Collingwood and has a worm gear and a warp extender. These features mean the tension is infinitely adjustable and the tension is also even.

Harrisville Rug Loom, Harrisville Designs

Other countermarche looms also work well for tapestry. An old standard is the Cranbrook loom now made by Schacht Spindle Company. The other popular one is made by Glimakra, a Swedish company.

Counterbalance looms work well for tapestry. My favorite variety, the Rio Grande walking loom, is popular in the American Southwest. They came to this continent with the Spanish and the Hispanic people of New Mexico and neighboring states use them still. They are called walking looms because you stand on the treadles as you weave to shift the shed.

Rio Grande walking loom

And the last kind of standard low-warp loom in the US is the jack loom. I will admit that most of these looms do not work as well for tapestry. The company that makes looms with heavy enough jacks to be very good for tapestry is Macomber. Other jack looms that I have used successfully for tapestry, though they don't have as much tension as I'd like, are the Schacht looms and the jack looms made by Harrisville Designs. If you have a Schacht Wolf Pup sitting in the corner, drag it out and try a tapestry on it.

Macomber jack loom in the factory

The other lesser known (in the USA) low-warp loom is the Aubusson loom. These are the looms that were used traditionally for tapestry in the Aubusson region of France and are loved by many people today. The shed is manipulated with treadles from underneath and there is no castle. Jean Pierre Larochette who started the San Francisco Tapestry workshop, was trained by weavers from Aubusson and uses one of these looms for much of his work.

Elizabeth Buckley is another American tapestry weaver who uses such a loom.

Julie Ruelle weaving on an Aubusson loom at the Cité Museum in Aubusson, France.

There are few low-warp types of looms that are small that I would recommend for tapestry. Occasionally you'll find a very sturdy table loom that does okay (Louet makes somoe). Rigid heddle looms and most table looms are generally very poor for tapestry due to their low tensioning ability. Most of these looms have tiny front and back beams held with little teeth, often plastic. These just can't produce the strong even tension that works so well for tapestry weaving.

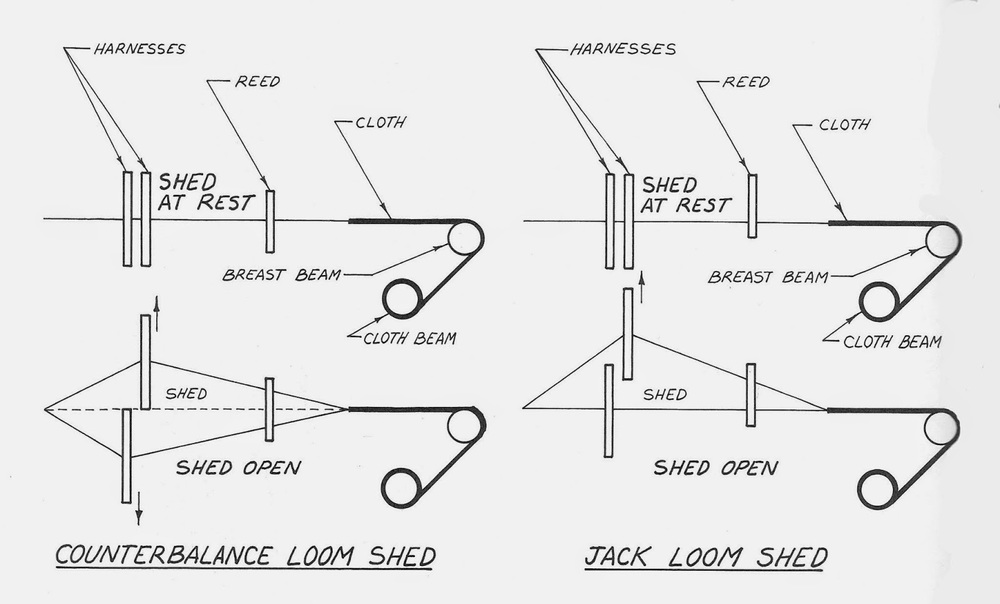

The diagram below shows you the major differences between the kinds of floor looms.

Counterbalance and countermarche looms work like the diagram on the left. Countermarche looms have a more complicated lamm mechanism that allows uneven numbers of harnesses to be raised or lowered at the same time (thus you could do a 3-1 twill for example). Counterbalance looms work with a roller system and when half of the harnesses go up, the other half must go down. Since tapestry is essentially a plain weave, either loom works.

Jack looms work like the diagram to the right. The harnesses are "jacked" up to create the shed. Sometimes the resting position does not have the warp running straight between front and back beams. The jacks actually push the warp down somewhat at rest. For tapestry, if you raise the tension on these looms, the warp pushes the jacks up and you don't get a shed at all.

Source: Broudy, E. (1979). The Book of Looms. New York: Van Nostrand Reinhold Company.

And just for fun, here is a loom which is pictured in Eric Broudy's book, The Book of Looms. Has anyone ever seen a loom like this? Apparently it can work as a jack, counterbalance, or countermarche loom. It was manufactured by Thought Products, Inc.

Source: Broudy, E. (1979). The Book of Looms. New York: Van Nostrand Reinhold Company.

Stay tuned for the next post with information about high-warp tapestry looms.